EN

What are you looking for?

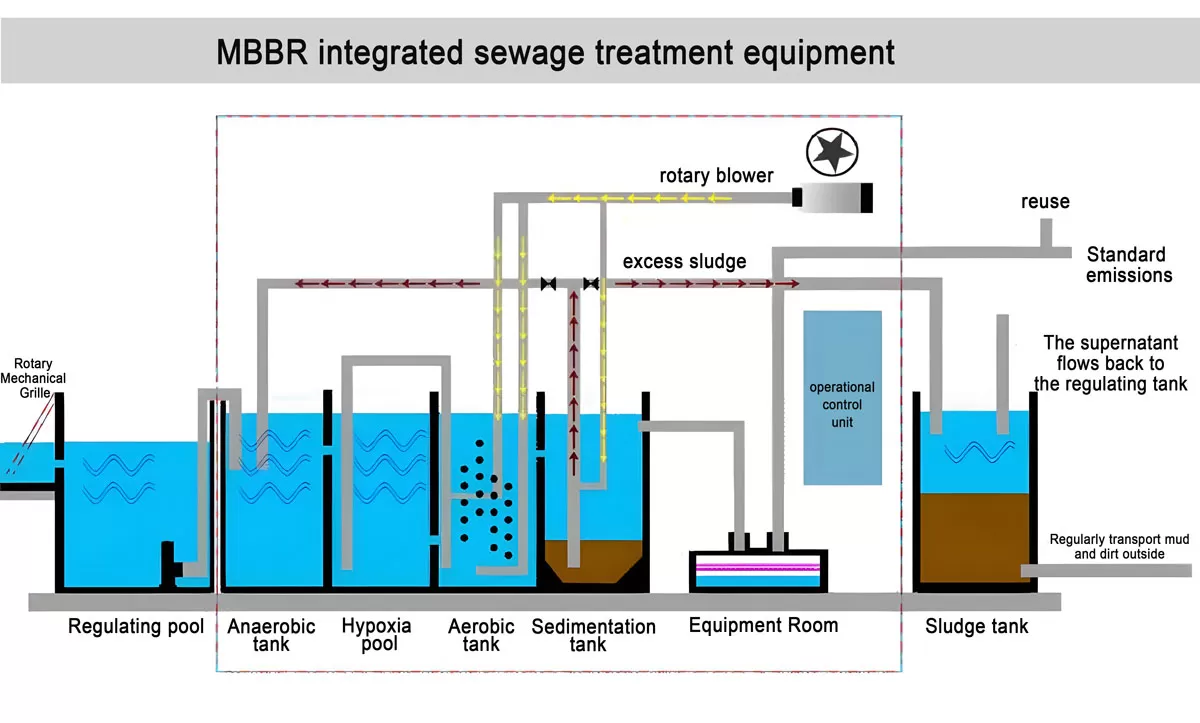

Wastewater undergoes a comprehensive five-stage treatment process within an integrated system to ensure safe discharge or reuse.

1. Pretreatment: Initial screening removes large solids like plastics and debris. Wastewater then enters an equalization tank to balance fluctuating flows and pollutant loads, providing stable conditions for subsequent treatment.

2. Biological Treatment (A²/O Process): This core section utilizes microorganisms:

Anaerobic Zone: Phosphorus-accumulating organisms release phosphate.

Anoxic Zone: Nitrates from the recycled mixed liquor are converted to nitrogen gas (denitrification).

Oxic Zone: Aeration supports organic matter decomposition, nitrification of ammonia, and phosphorus uptake.

3. Sedimentation: Treated water flows to a clarifier where gravity separates biological sludge. Most sludge is returned to the bioreactor to sustain microbial activity; excess is removed as waste sludge.

4. Disinfection: The clarified effluent is disinfected using chlorine compounds or ultraviolet light to destroy pathogenic bacteria, ensuring public health safety.

5. Discharge/Reuse: The final treated water complies with regulatory standards for environmental discharge or applicable reuse purposes.

| Model | Processing Capacity | Treatment Process | Size (Dimension) | Material | Air Blower | Sewage Pump | Occupy Area | |||

| Model | Power | Units | Model | Power | ||||||

| HYYTH-20 | 20m3/d | Contact oxidation | 7*2*2m | SUS/SS | HZ-15S | 0.105kW | 2 | ISG15-80 | 0.18kW | 24m2 |

| MBR membrane | 6.5*2*2m | SUS/SS | HJB-550 | 0.55kW | 2 | ISG20-100 | 0.55kW | 23m2 | ||

| HYYTH-30 | 30m3/d | Contact oxidation | 6*3*2.5m | SUS/SS | HZ-251S | 0.55kW | 2 | ISG15-80 | 0.18kW | 28m2 |

| MBR membrane | 7*2*2.5m | SUS/SS | HZ-251S | 0.55kW | 2 | ISG20-100 | 0.55kW | 24m2 | ||

| HYYTH-50 | 50m3/d | Contact oxidation | 9*3*2.5m | SUS/SS | HZ-40S | 0.75kW | 2 | ISG40-100A | 0.37kW | 40m2 |

| MBR membrane | 8.5*3*2.5m | SUS/SS | HZ-50S | 1.5kW | 2 | ISG25-125A | 0.55kW | 38m2 | ||

HYYTH-100 | 100m3/d | Contact oxidation | 14*3*3m | SUS/SS | HZ-401S | 1.5kW | 2 | ISG40-100A | 0.37kW | 60m2 |

| MBR membrane | 10.7*3*3m | SUS/SS | HZ-601S | 4kW | 2 | ISG40-100A | 0.37kW | 47m2 | ||

| HYYTH-200 | 200m3/d | Contact oxidation | 26*3*3m | SUS/SS | HZ-501S | 2.2kW | 2 | ISG40-100(I)A | 0.75kW | 108m2 |

| MBR membrane | 22.5*3*3m | SUS/SS | HZ-1001S | 4kW | 2 | ISG40-100(I)A | 0.75kW | 94m2 | ||

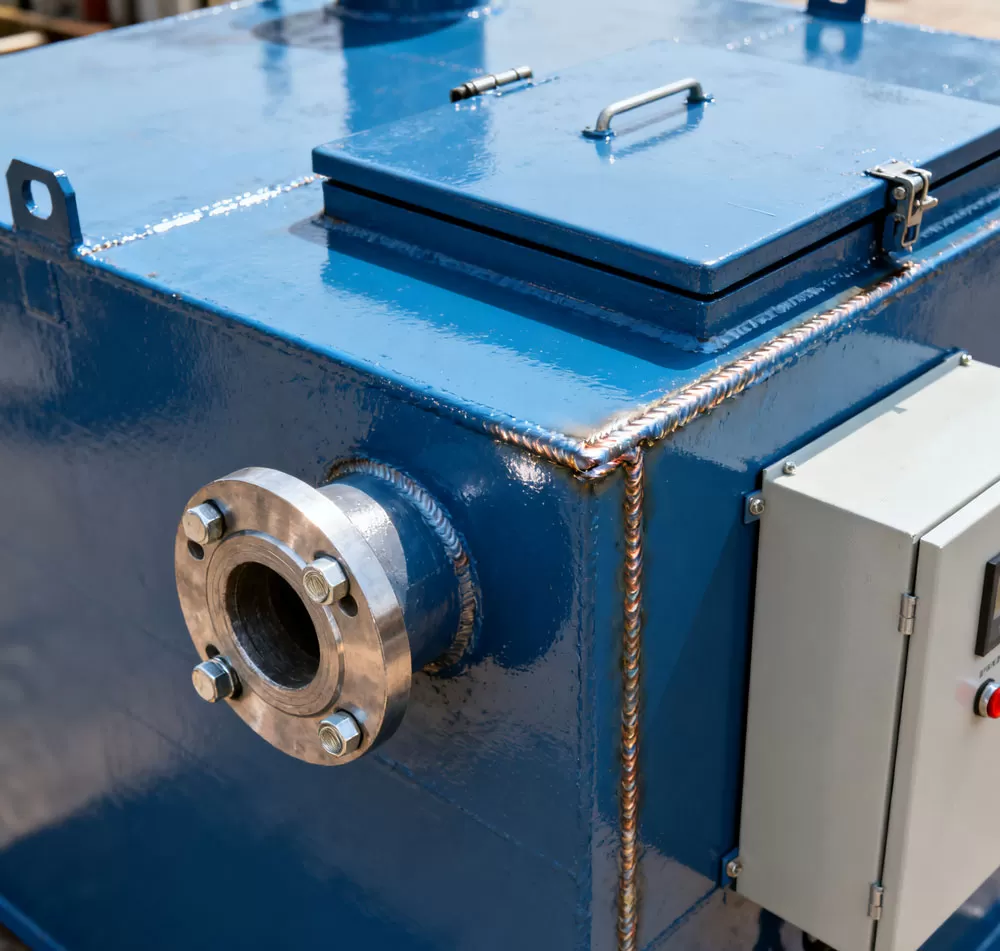

The most common ones are carbon steel anti-corrosion and fiberglass reinforced plastic (FRP). Advanced ones will use stainless steel (such as 304 or 316L).

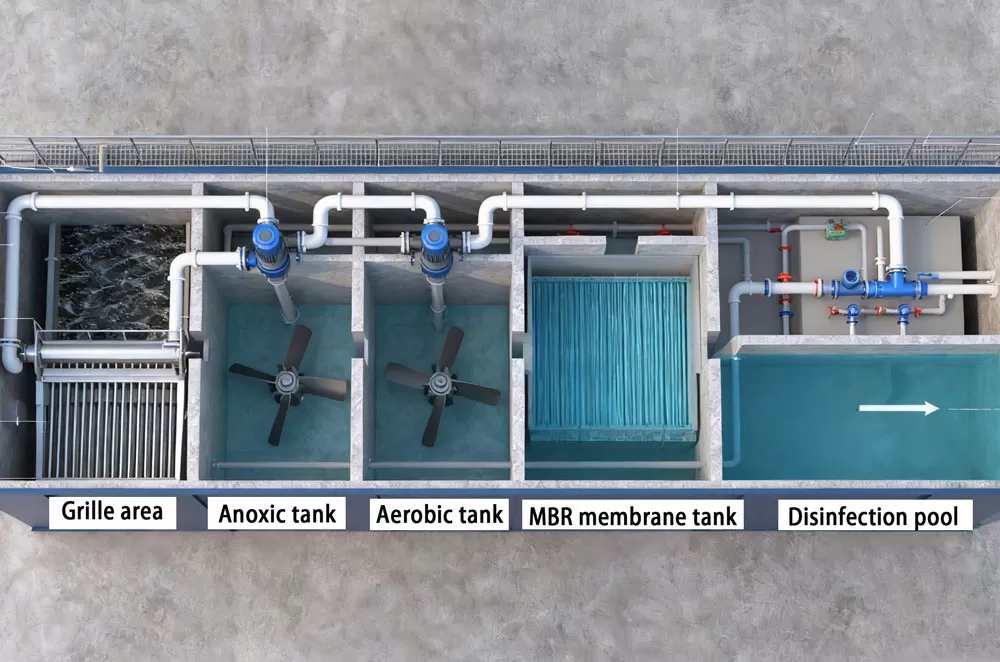

The biochemical treatment unit (anoxic tank, aerobic tank, MBBR membrane tank) is the core of the integrated sewage treatment equipment.

MBBR membranes are crucial for high-quality effluent reuse, saving space, and enhancing treatment efficiency and stability.

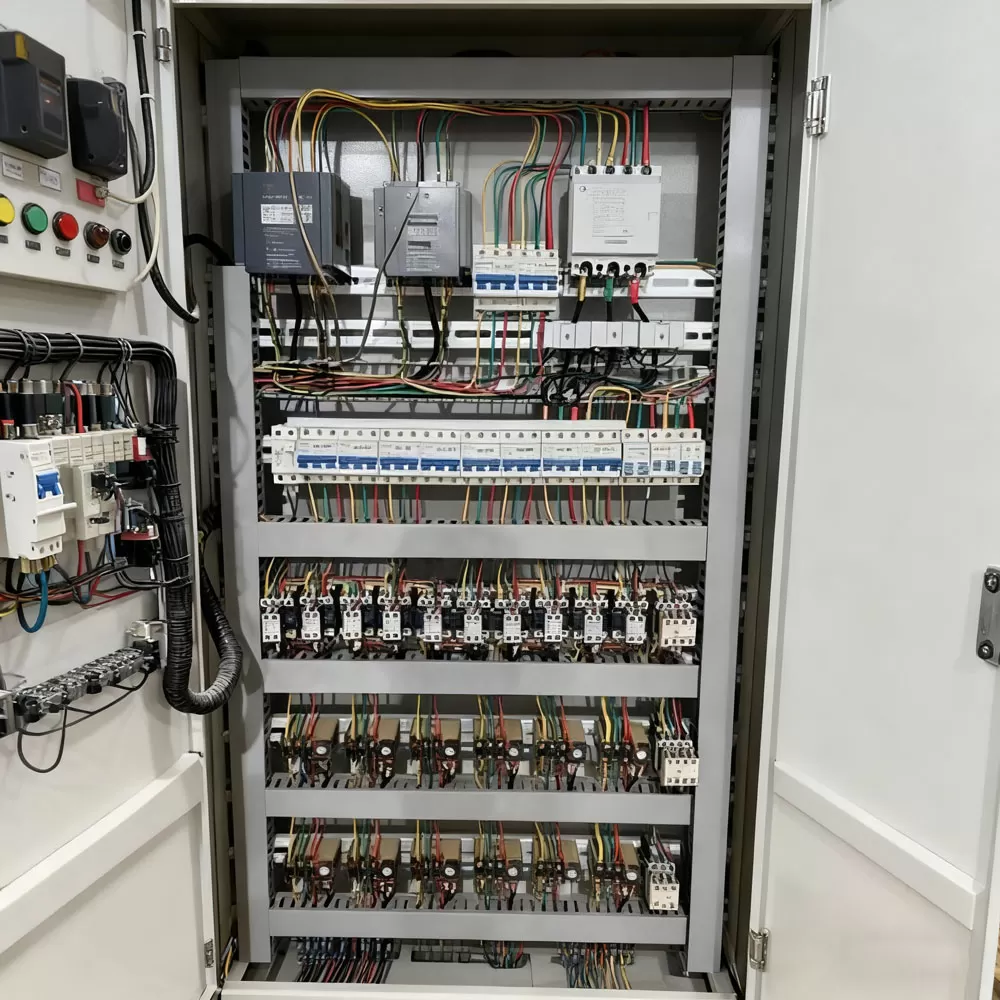

High degree of automation, easy to operate and maintain, supports remote monitoring.

Core Challenges

Geological complexity: Beach geology, loose and high groundwater level.

Space limited: The resort has a compact layout and limited available space.

Strict standards: The effluent must meet the reuse standards (for irrigation or flushing) to protect coral reefs.

Highly corrosive: high-salt and high-humidity oceanic climate.

Solution

Adopt containerized integrated MBR sewage treatment equipment.

Process: pretreatment+MBR membrane bioreactor+disinfection.

Advantages: Good effluent quality, small footprint, high degree of automation.

Key points for installation implementation

Foundation: Pour concrete platform to solve the problem of sand settlement.

Lifting: The equipment is prefabricated as a whole, shipped directly by sea, lifted into place, and installed quickly.

Anti corrosion: The equipment and pipelines are made of weather resistant steel, advanced coatings, and UPVC/SS316 stainless steel materials to resist salt spray corrosion.

Intelligent operation and maintenance: equipped with a remote monitoring system to achieve unmanned operation and remote diagnosis.

Project Achievements

The equipment was quickly put into operation, and the stable effluent reached the reuse standard. It was used for garden irrigation and toilet flushing, achieving water resource recycling and perfectly supporting the ecological concept of the resort.