EN

What are you looking for?

Core Principle

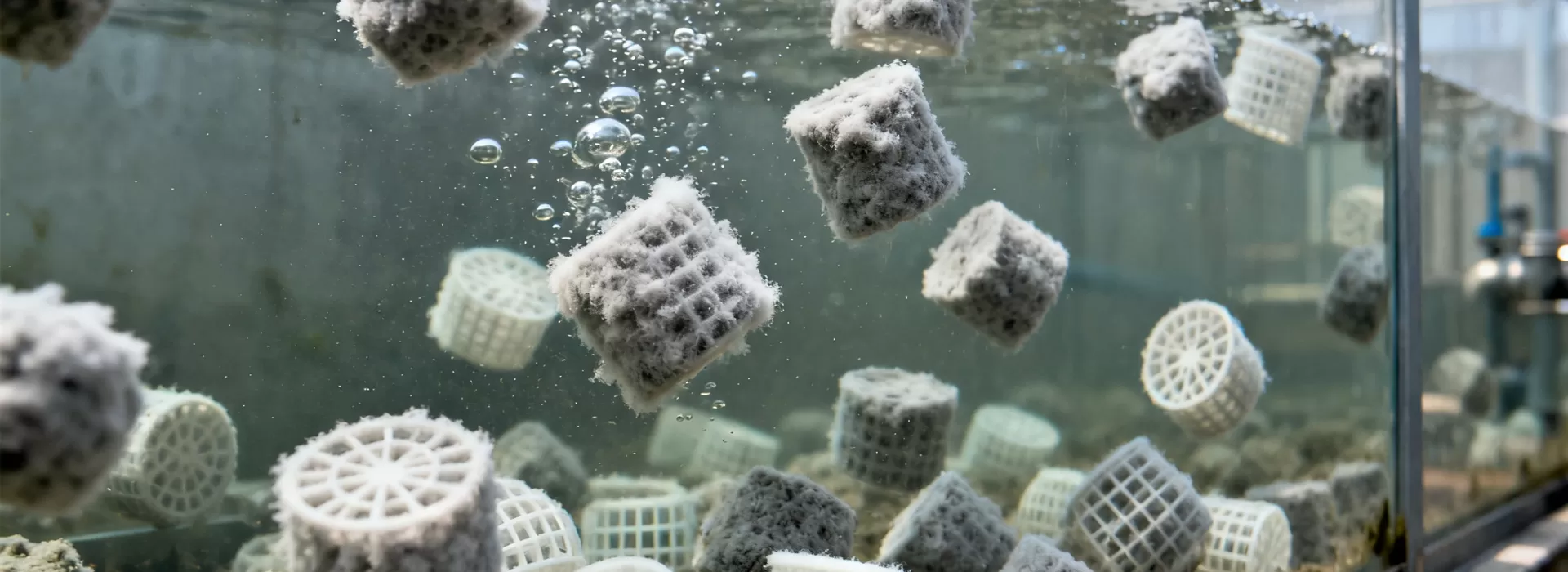

MBBR filler (HDPE, density 0.94-0.97g/cm³) fluidizes under aeration, creating a gas-liquid-solid environment to support microbial attachment and biofilm formation for pollutant degradation.

Efficient Nitrogen & Phosphorus Removal

It forms aerobic-anaerobic microenvironments for simultaneous nitrification-denitrification, separates functional bacteria, and enhances nitrogen-phosphorus removal.

Shock Resistance & Stability

High specific surface area (500-800m²/m³) hosts massive microorganisms, resists water fluctuations, avoids clogging, and requires no backwashing.

Flexible Adaptability

Directly integrable into existing systems, with dosage adjustment for quick, low-cost upgrading, suitable for municipal and industrial wastewater treatment.

MBBR biological filler is a game-changer in biological water treatment, offering superior microbial adhesion, high mass transfer efficiency, and robust pollutant degradation. Its compact design saves space, simplifies maintenance, and adapts to diverse wastewater types. Ideal for export, it has proven effective globally. Case: Our exported fillers enabled a Southeast Asian textile factory to reduce COD by 85% and BOD by 82%, meeting local discharge standards efficiently and cost-effectively.

High density polyethylene (HDPE) is an ideal material for MBBR fillers: it has strong chemical stability, acid and alkali resistance, corrosion resistance, long-term stability within pH 2-12, and a service life of 8-10 years; Excellent physical properties, with a density close to water (0.94-0.97g/cm ³), uniform fluidization, high strength, and good wear resistance; The surface has undergone special treatment, with outstanding biocompatibility and easy attachment of microorganisms, reducing the film-forming time to 7-10 days.