EN

What are you looking for?

Contaminant Removal

NF systems (1–10nm pores) filter dissolved organics, heavy metals, and pesticides, while retaining beneficial minerals (calcium, magnesium) — a key balance vs. RO/UF.

Lower Energy & Costs

Requires 30–50% less pressure than RO, cutting energy use. Membranes last 2–3 years (with maintenance), reducing replacement expenses.

Wide Applications

Used for residential drinking water, food/beverage concentration, and industrial wastewater recycling, fitting multiple scenarios.

Eco-Friendly

Boasts 70–85% water recovery (higher than RO's 50–70%), generating less waste. Most models avoid chemicals, reducing environmental impact.

Case Study:

NF nanofiltration is widely used for selective separation, softening, and organic removal in industrial water treatment. It effectively removes divalent ions and micropollutants, enabling water reuse and resource recovery. A key application is in the semiconductor industry, where NF produces ultra-pure water by rejecting over 98% of divalent salts and organic matter, protecting downstream processes and ensuring high product yield.

Export Case Study:

A bottled water plant in the UAE uses a Chinese-made NF system to treat brackish groundwater. It effectively reduces nitrates, sulfates, and hardness, ensuring the final product meets stringent international bottled water standards, demonstrating the global reliability of our technology.

Feed Supply: Pretreated feed water is pressurized by a high-pressure pump.

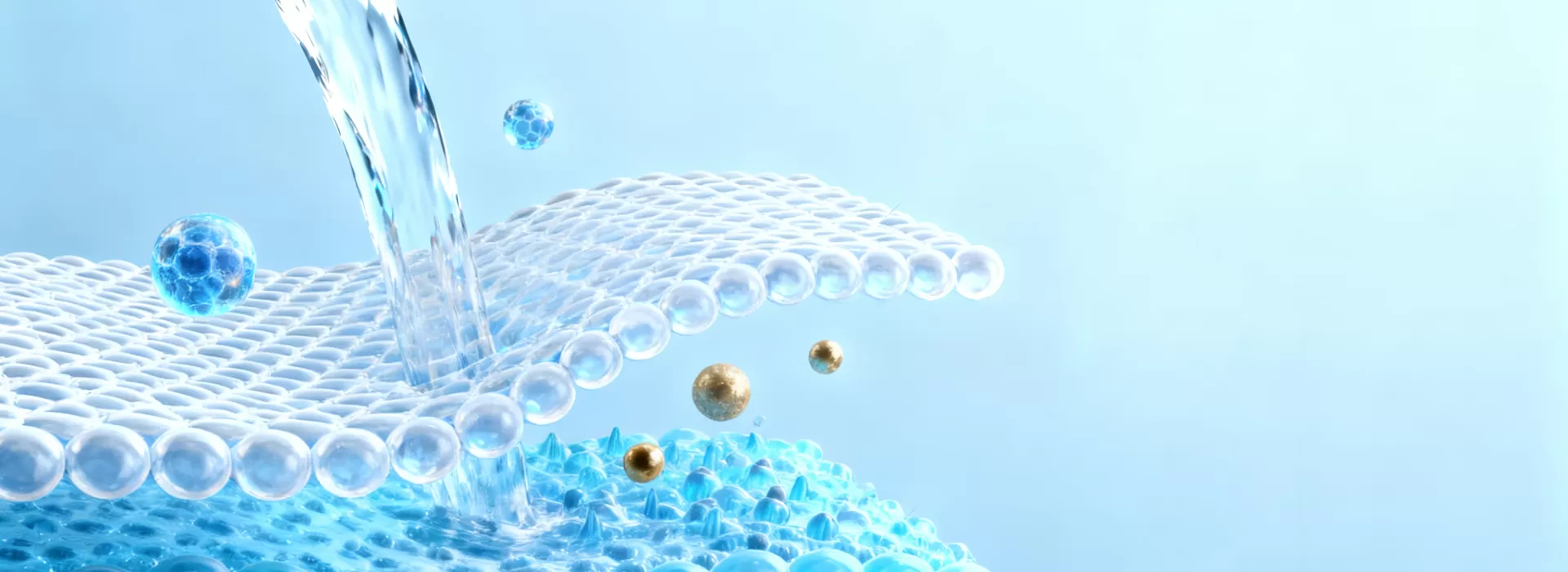

Membrane Separation: Water is forced through semi-permeable NF membranes.

Selective Filtration: These membranes selectively reject divalent ions (e.g., sulfates, calcium), organic matter, and viruses, while allowing most monovalent ions (e.g., chloride, sodium) to pass.

Stream Separation: The system produces two streams: the purified permeate (product water) and the concentrated reject (waste stream).