EN

What are you looking for?

Water purification treatment equipment for electronic equipment production is a specialized system designed to purify raw water (e.g., tap water, groundwater) into ultra-pure water (UPW) that meets the stringent requirements of electronic manufacturing processes. In the production of electronic components such as semiconductors, printed circuit boards (PCBs), and displays, water is used for cleaning, rinsing, and processing. The equipment removes impurities, ions, particulates, and microorganisms to prevent contamination, ensure product quality, and protect sensitive manufacturing equipment.

Ultra-Pure Water Quality Assurance

Produces ultra-pure water with extremely low conductivity (e.g., <0.055 μS/cm), minimal total organic carbon (TOC), and near-zero particulates, meeting standards like SEMI F63 or ASTM D5127 for electronics manufacturing.

Multi-Stage Purification Process

Pre-treatment: Sand filtration, activated carbon filtration, and softening to remove suspended solids, chlorine, and hardness.

Core Purification: Reverse osmosis (RO), electrodeionization (EDI), or mixed-bed ion exchange to achieve ultra-low ion content.

Disinfection: UV sterilization and ozonation to eliminate bacteria, viruses, and organic compounds.

Final Filtration: Sub-micron (0.05–0.1 micron) or nanofiltration to remove trace particulates and ensure particle-free water.

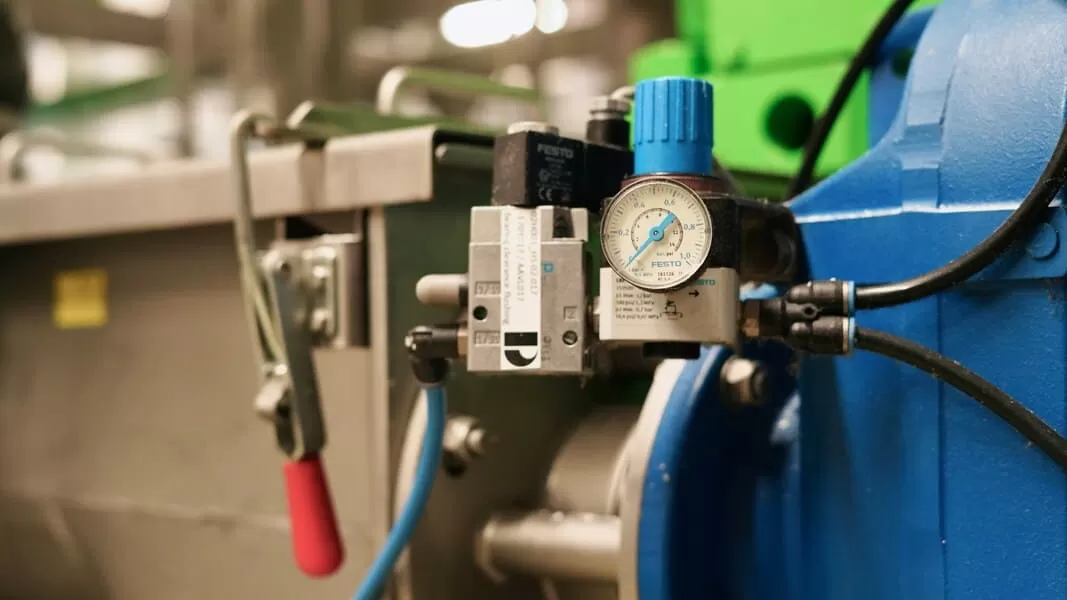

Automated Control

Equipped with PLC or touchscreen systems for real-time monitoring of water quality parameters (e.g., resistivity, TOC, particle count) and fully automated operation.

Hygienic Design

Uses high-grade stainless steel (SUS316L) or specialized plastics for pipelines and storage tanks, with Clean-in-Place (CIP) systems to prevent contamination and maintain water purity.

Flexible Configuration

Customizable to meet specific production needs, water quality standards (e.g., 18.2 MΩ·cm resistivity for semiconductors), and raw water characteristics.

Semiconductor Manufacturing: Ultra-pure water for wafer cleaning, etching, and rinsing to prevent defects and ensure high yields.

Printed Circuit Board (PCB) Production: Water for cleaning and rinsing PCBs to remove flux residues and prevent corrosion.

Display Manufacturing: Purified water for cleaning LCD, OLED, or LED panels to ensure clarity and defect-free surfaces.

Component Cleaning: Water for rinsing sensitive electronic parts to avoid ionic or particulate contamination.

Cooling Systems: High-purity water for cooling equipment in cleanroom environments to prevent scaling or corrosion.